S5 SUB 5 PPM NOx Firetube Boiler Burner

- Simplified controls to achieve lower price points

- Can be built to be upgradable to near zero NOx levels (Sub 2.5 ppm) for insurance against future regulations

Rogue Combustion now offers a superior solution

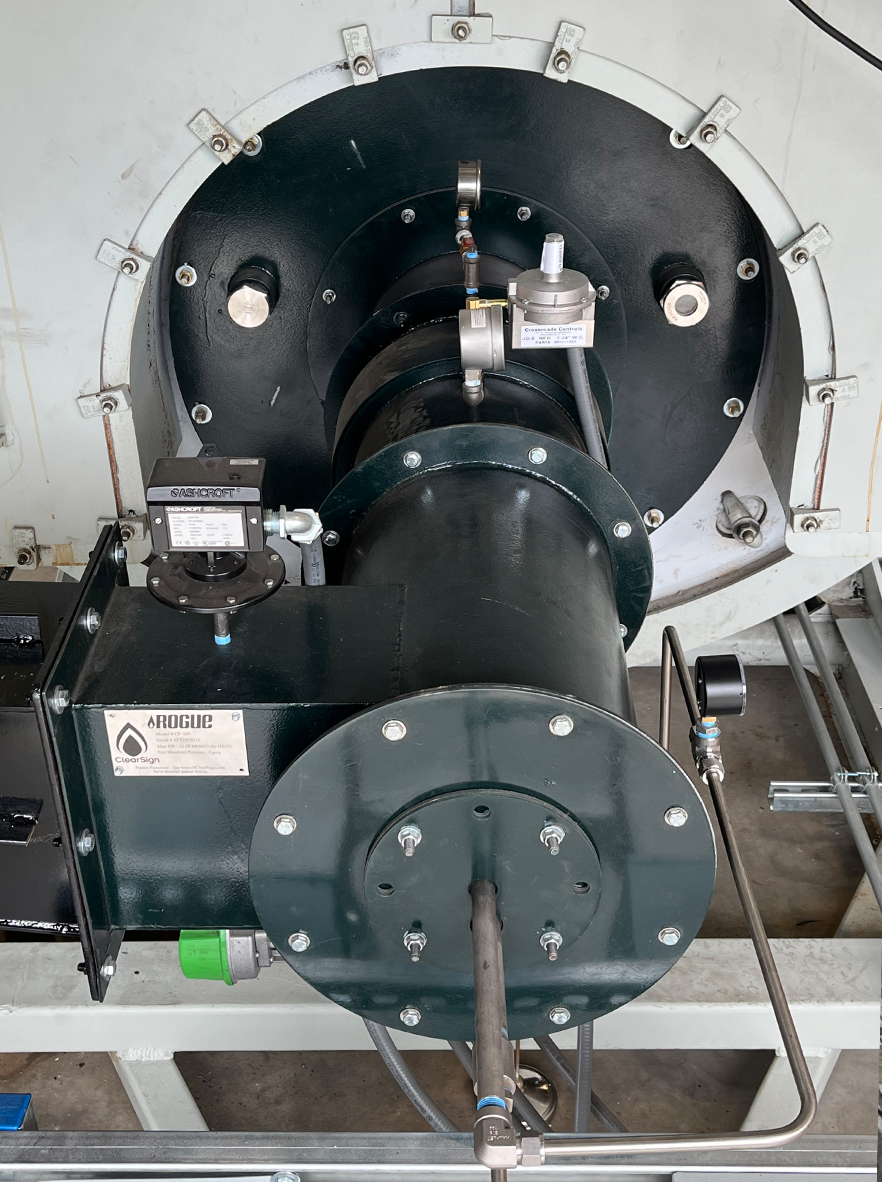

The Rogue Combustion Boiler Burner with ClearSign Core™ Technology.

Simply put, this product delivers SCR level performance in a compact burner that is both cost effective and simple to operate and maintain. Thoroughly tested in a variety of boiler configurations, the Rogue Combustion Boiler Burner with ClearSign Core™ Technology can yield sub 2.5 ppm NOx without costly catalysts, hazardous chemicals, extra ducts or controls.

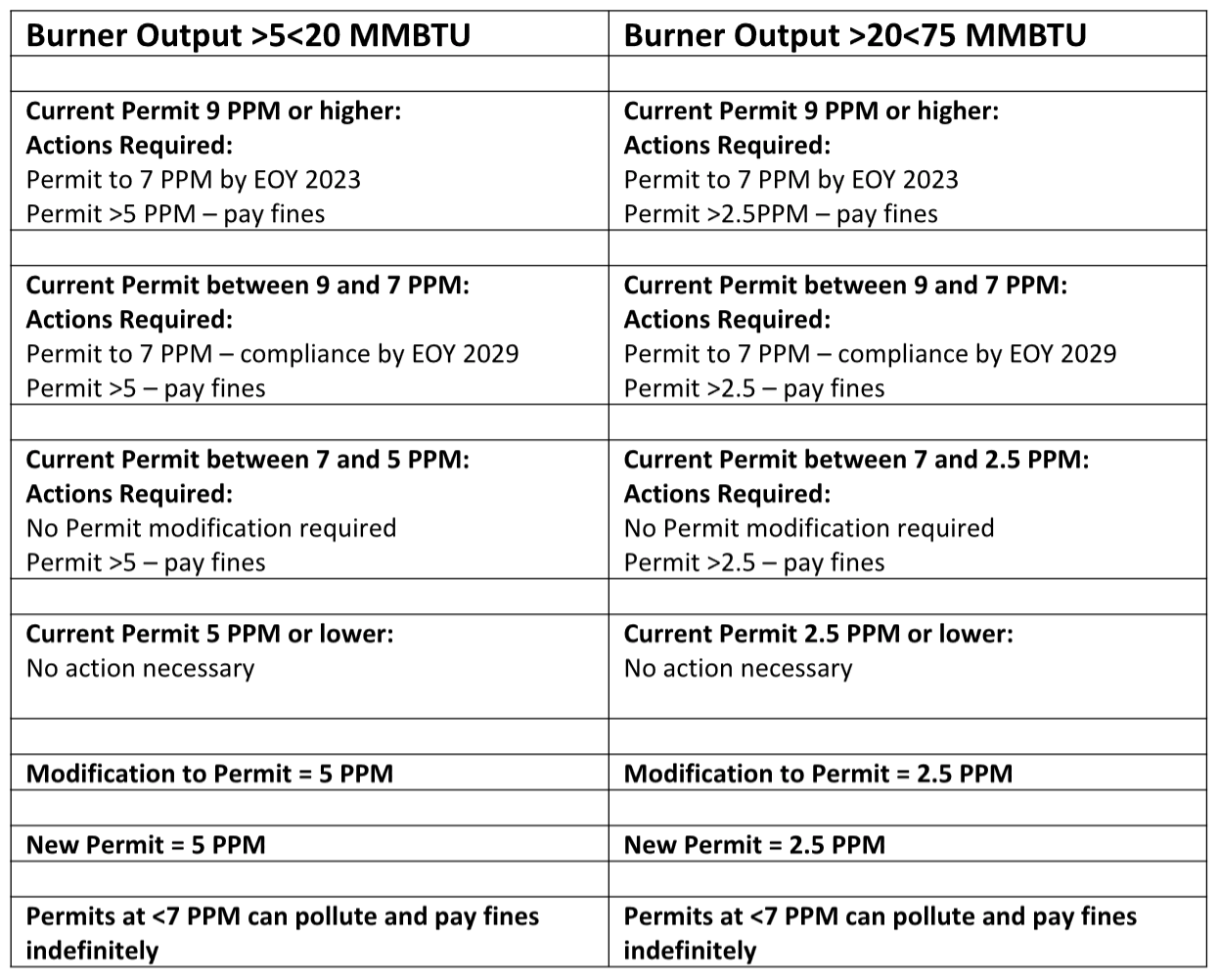

California has two air districts that have the most stringent NOx requirements in the country. SJVAPCD: San Joaquin Valley Air Pollution Control District and SCAQMD: South Coast Air Quality Management District. The NOx limit in these non-attainment areas for boilers less than 20 MMBTU per hour is 5 ppm corrected to 3% Oxygen. By adapting the ClearSign Core Technology TM, that is at the heart of its Near Zero NOx (NZN) burner system, Rogue has able to create the cost-effective Rogue S9 (Sub 9 ppm NOx) burner to comply with these regulations.

*applicable regulatory authority must be consulted for any specific case.

Near Zero / Ultra Low NOx <2.5ppm

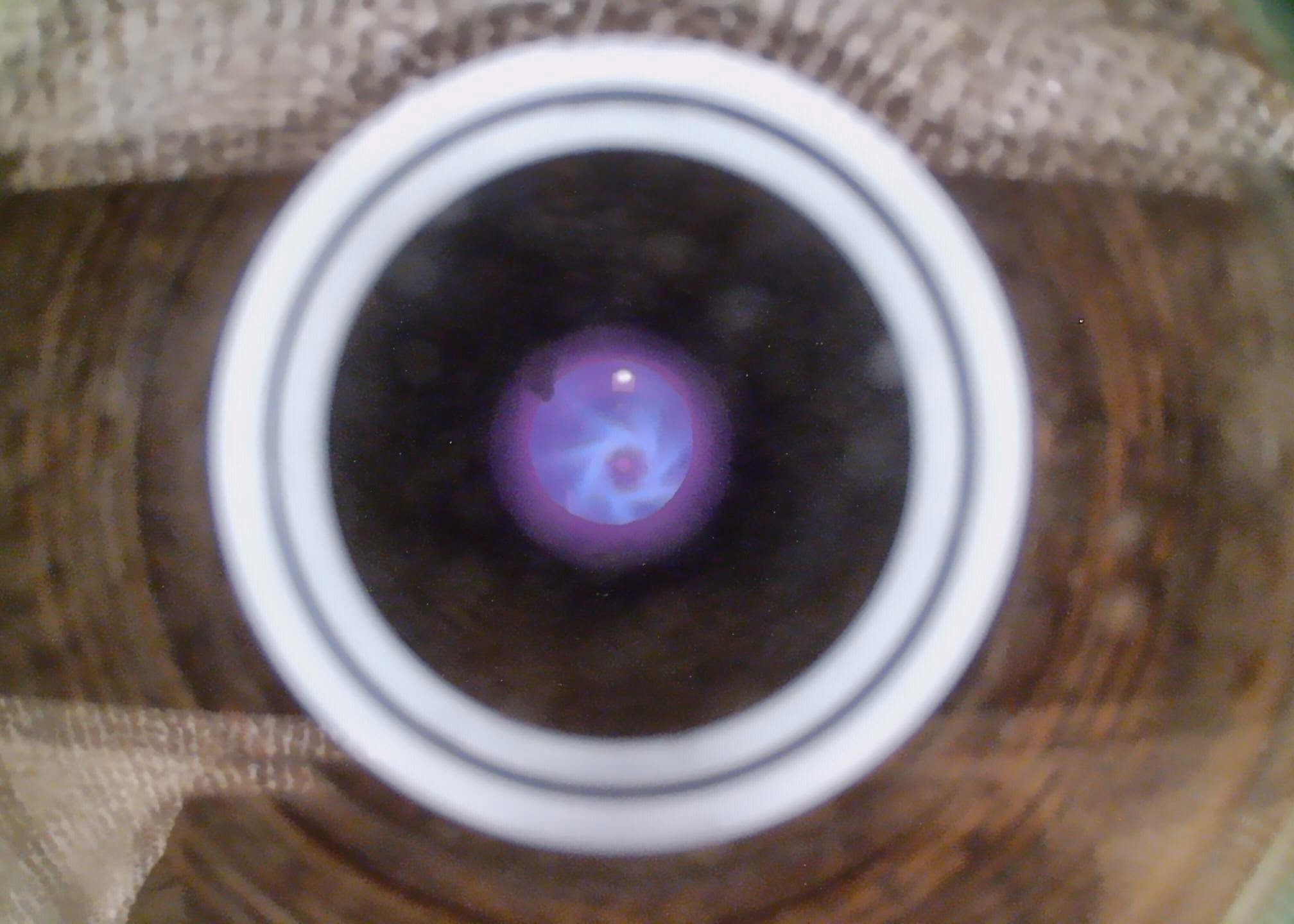

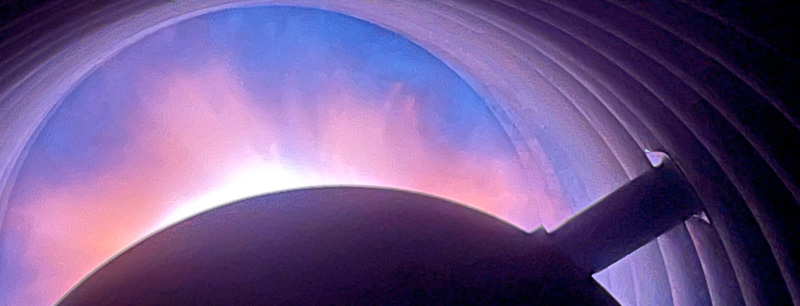

Premixed combustion, entrainment of spent flue gases, and a distal flameholder enable NOx levels never before seen in the industry - all without the use of reagents, catalysis and/or high excess air conditions.

Ultra Low CO <5ppm

Thorough premixing of the incoming fuel and air mixture ensures a highly efficient combustions at temperatures that ensure complete CO burnout.

Turndown up to 5:1

Increased combustion intensity and robust flame holding generate wide stability envelopes and ensure a high degree of turndown.

High Efficiency

Stable operation at low excess air levels ensures highly efficient combustion unlike competing high excess air solutions.

Capacity

The Rogue Combustion Boiler Burner with ClearSign Core™ Technology solutions have ranges from as low as 4MMBTU/hr and up to 100MMBTU/hr, a true testament to the breadth and scalability of the technology.

Retrofit Solution

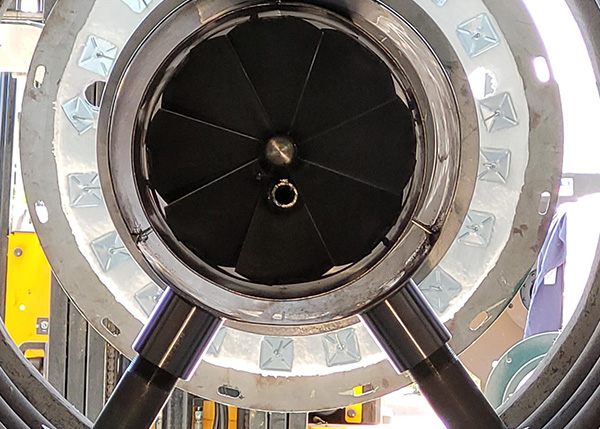

Fits most standard furnaces without modifications to the boiler. External FGR is not required, so no additional high temperature ducting is needed. Front plate is custom designed to connect to customer specific boiler.

MARKET ASSESSMENT

Emerging Ultra Low-NOX Burner Technologies

Prepared by ICF for submission to the Southern California Gas Company as part of the Gas Emerging Technologies

The GET Program Project

The project will research emerging Ultra-low NOx (ULN) Burner technologies to provide actionable recommendations of technologies and gaps for further study by the GET program. This project will research and evaluate cost-effective, efficient, and ultra-low emission burner technologies including burner geometry designs, and add-on controls. A final report documenting the findings will be developed, which will provide investor-owned utilities with information to assess the retrofit feasibility, add-on control feasibility, and the operating cost of these new ULN burner technologies.

ROGUE BURNER

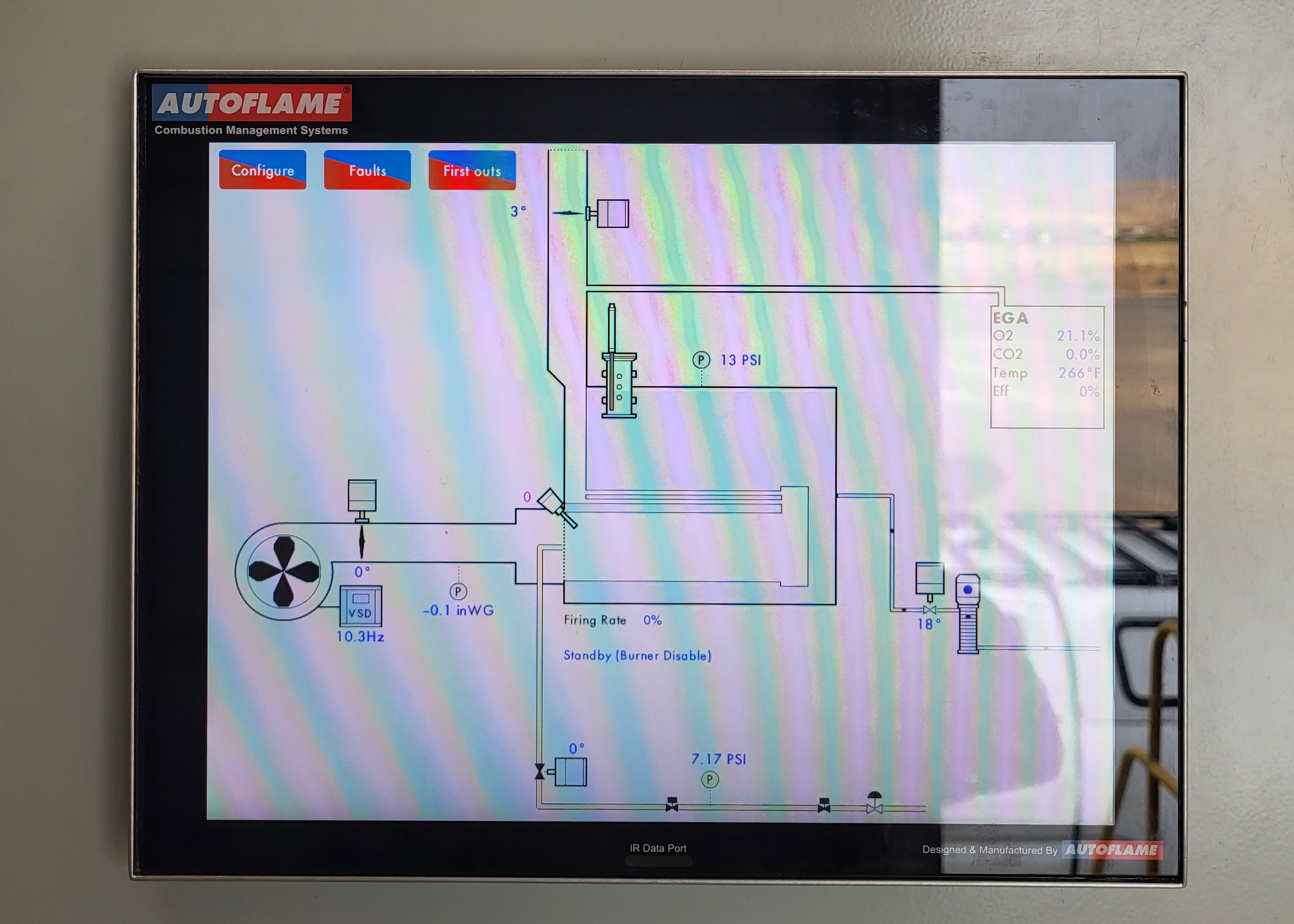

“Rogue Combustion, LLC partnered with ClearSign™ Combustion Corporation which resulted in the Rogue Burner. Rogue specializes in fire tube boiler burners, which can be supplied for new boilers or retrofitted into existing boiler equipment. The complete boiler system includes the burner, blower, fuel gas train, combustion controls, and installation. Compared to other boiler burners, this boiler burner system has no need for costly catalysts, chemicals, or extra ducts or controls.

This boiler burner using the ClearSign Core ™ technology has exceptional flexibility for controlling NOx emissions. During the site visit, we were able to tweak the burner to operate close to sub 1 ppm NOx. From conversations with representatives, they claimed that they have not yet even come close to “optimizing” the burner.”

FREQUENTLY ASKED QUESTIONS

The technology provides unprecedented emissions levels (~2.5ppm NOx at 3% O2) compared to traditional equipment without the use of reagents, high excess air conditions or degradations in thermal efficiency

No, the Clearsign technology can be operated in exactly the same manner as a legacy burner with regard to start up, ramp rate and shut down protocols.

Basically none. The Clearsign Core™ technology is a retrofittable technology that is easily inserted through the same boiler burner openings as the OEM burner.

A distal metallic flameholder and continuous pilot are located downstream of the conventional burner location. Fuel pokers inject fuel downstream and entrain FGR. The cold charge thoroughly mixes as it approaches the flame holder. Thorough mixing of all gas streams, a continuous pilot, and robust flame anchoring ensure excellent combustion stability and superior emissions performance over the operating envelope.